Alpenta je jednou z předních společností v oblasti výroby zařízení pro chlazení a vzduchotechniku v České republice

Alpenta je jednou z předních společností v oblasti výroby zařízení pro chlazení a klimatizaci v České republice. Za rychlým rozvojem firmy Alpenta stojí lidé s dlouholetými zkušenostmi v branži HVAC. Základním motorem růstu naší společnosti je budování silných vztahů s profesionálními partnery v oblasti distribuce chladících a klimatizačních zařízení.

Převážná část naší výroby je určena pro export. Naše zařízení realizují systémy klimatizace v budovách letišť, obchodních centrech, nemocnicích, datových centrech a dalších komerčních objektech.

Dodáváme rovněž chladící agregáty pro průmyslové využití při skladování a výrobě – pro potravinářství, výrobu plastů, farmaceutický průmysl atd.

Profil společnosti

Neustále rozvíjíme technologii a systém řízení chladících agregátů s cílem zvyšování energetické efektivity a spolehlivosti. Naše vlastní testovací stanice s vodním zásobníkem 16㎥ umožňuje provozní analýzy práce chladičů kapalin při různých typech energetické zátěže.

Vzduchem chlazené chillery ALPENTA jsou standardně projektovány s možností aplikace systému freecooling (volného chlazení) – od nejmenších velikostí jednotek SAC1 až po největší agregáty typu AAC18.

Reverzní chillery s funkcí tepelného čerpadla jsou vhodné pro objekty s energetickou náročností od 10 kW až po velké komerční budovy jako letiště, obchodní centra nebo nemocnice.

Každý chiller je při finalizaci výrobního procesu podroben funkčnímu testu.

Naše zkušenosti, široká nabídka verzí ve všech modelových řadách, agilní strategie výroby a profesionalita nám umožňují individuálně řešit komplexní potřeby chlazení.

Výroba klimatizačních jednotek obchodní značky AEROSTAR je realizována na základě licence společnosti Ventservice. Kvalita a zkušenost v oboru projektování a výroby vzduchotechnických jednotek AEROSTAR je rovněž potvrzena certifikátem EUROVENT (jednotky GreenSTR).

Administrativní část společnosti ALPENTA sídlí v Technologickém Centru Hradec Králové a moderní výrobní závod se nachází v průmyslové zóně přilehlé k automobilce Škoda Auto.

MANAGEMENT KVALITY

Alpenta Management Systém (AMS)

Otázka kvality hraje prvořadou úlohu při technicky a procesně velmi náročné výrobě chladících zařízení. Dlouhodobě realizujeme politiku neustálého zlepšování kvality ve všech perspektivách řízení organizace.

Náš interní systém komplexního zajištění kvality AMS byl posouzen a následně certifikován ve shodě s požadavky a doporučeními standardu ČSN EN ISO 9001:2016

„ALPENTA s.r.o. zavedla a uplatňuje systém kvality pro konstrukci a výrobu chladicích a klimatizačních zařízení podle ČSN EN ISO 9001: 2016.“

společenská zodpovědnost

Společenskou odpovědnost v oblasti ekonomické, sociální a environmentální

vnímáme jako neodmyslitelnou součást naší firemní politiky.

Firma ALPENTA s.r.o. přijímá tento etický kodex jako soubor základních hodnot a přístupů k podnikání, kterými se řídí při své podnikatelské činnosti. Společnost řadí mezi své nejdůležitější úkoly zachování dobré pověsti a důvěry všech zainteresovaných stran.

Dodržování etického kodexu ze strany společnosti je jejím morálním závazkem upravujícím jednání zaměstnanců vůči společnosti, odběratelům a ostatním obchodním partnerům, orgánům státní správy a veřejnosti. Společnost realizuje všechny aktivity eticky a s dobrými úmysly za přísného dodržování všech zákonných norem.

Vztahy s odběrateli

Čestnost a rovnost vůči odběratelům pokládá společnost za základ úspěšného a trvalého obchodního vztahu. Společnost dbá na to, aby její výrobky odpovídaly deklarovaným

kvalitativním parametrům a požadavkům obsaženým v národních a mezinárodních normách.

• Společnost si je vědoma důležitosti termínové přesnosti veškerých dodávek.

• Společnost nepoužije při snaze realizovat prodej svých výrobků žádné jiné prostředky, než jsou obchodní metody legitimně uznané.

• Společnost považuje korupční praktiky jakéhokoliv druhu za nepřípustné.

• Informace odběratelů považuje společnost za důvěrné.

Vztahy s dodavateli

• Společnost nepoužívá při koupi výrobků služeb apod. žádné jiné prostředky, než jsou legitimně uznané obchodní metody, a nikdy nezneužívá své postavení na trhu.

• Společnost považuje korupční praktiky jakéhokoliv druhu za nepřípustné.

• Společnost respektuje veškerá smluvní ujednání a platební morálku.

• Veškeré informace o vztazích s jejími dodavateli pokládá společnost za důvěrné.

Vztahy k zaměstnancům

Vztahy k zaměstnancům zakládá společnost na úctě k důstojnosti každého člověka. Společnost přijímá a povyšuje zaměstnance na základě jejich způsobilosti pro danou práci bez jakékoliv politické, rasové, náboženské či národnostní diskriminace, bez ohledu na pohlaví, věk, stav, nebo nezpůsobilost, která se nevztahuje k pracovním úkolům. Společnost netoleruje sexuální, fyzické nebo psychické obtěžování zaměstnanců.

Společnost se snaží vytvářet hygienicky nezávadné, bezpečné pracovní prostředí, příznivé pracovní klima a příznivé podmínky pro zvyšování odborné úrovně zaměstnanců. Společnost vyžaduje, aby zaměstnanci dbali zásad bezpečné práce, dodržování a využívání stanoveného fondu pracovní doby. Společnost vyžaduje, aby ve vztahu k majetku společnosti zaměstnanci nejednali v rozporu s oprávněnými zájmy zaměstnavatele a řádně hospodařili se svěřenými prostředky i v zájmu ochrany majetku zaměstnavatele. Informace, které zaměstnanci o společnosti získají při výkonu své práce, nesmějí používat pro osobní zisk ani pro jiný účel, než pro který byly určeny. Společnost zajišťuje pravidelné odměňování svých zaměstnanců za vykonanou práci včetně řádné výplaty mezd ve sjednaných termínech. Společnost prosazuje jako základní strategii soutěž na trhu založenou na samotném produktu, kvalitě nabízených služeb a cenové konkurenceschopnosti. Proto je přísně zakázáno neúměrné hoštění či dary dodavatelům a zákazníkům, stejně jako přijímání neúměrných darů a hoštění od zákazníků či dodavatelů. Ve společnosti se pro řešení případných pracovních sporů mezi společností a zaměstnanci přednostně používají vyjednávací procedury.

Vztahy k orgánům státní a regionální správy

Společnost bere při své podnikatelské činnosti v úvahu také zájmy širšího společenského okolí včetně zájmů národních a regionálních. Společnost komunikuje s orgány státní správy s využitím pravdivých informací o společnosti. Společnost dbá na řádné vedení účetnictví a včasné placení svých finančních závazků k orgánům státní správy a samosprávy. Společnost individuálně zvažuje a je přístupná charitativním aktivitám a sponzoringu amatérského sportu.

Ochrana životního prostředí

Společnost má trvalý zájem na zlepšování kvality životního prostředí. Společnost se aktivně podílí na odstraňování následků své podnikatelské činnosti a úpravou technologických postupů se snaží o minimalizaci dopadů výrobního procesu na životní prostředí. Společnost informuje své okolí o svém environmentálním programu. Společnost respektuje při podnikatelské činnosti normy stanovené pro oblast odpadů, emisí apod.

Vztahy s konkurencí

Společnost si počíná v konkurenčním boji rázně, ale čestně. Společnost nepoškozuje reputaci konkurentů. Společnost dbá, aby zaměstnanci ve styku s konkurencí respektovali důvěrnost obchodních informací či jinak důvěrných informací. Společnost se nepokouší nečestnými způsoby získat informace o podnikání konkurentů. Společnost nepoužívá restriktivní obchodní praktiky.

Vztah zaměstnanců ke společnosti

Zaměstnanci jsou povinni ochraňovat majetek společnosti a zajistit jeho efektivní využívání. Neschválené osobní využívání majetku společnosti všeho druhu je přísně zakázáno. Zaměstnanci mají povinnost zachovávat mlčenlivost o informacích, které jim společnost nebo její klienti svěřili i po ukončení pracovního poměru. Zaměstnanci jsou povinni podávat přesné a kompletní informace vedoucím zaměstnancům společnosti, vnitropodnikovým a nezávislým auditorům a všem dalším osobám, které mají oprávnění k získávání informací.

Dodržování etických zásad

Každý vedoucí zaměstnanec odpovídá za seznámení svých podřízených s obsahem kodexu. Hodnotový rámec řízení společnosti je založen na předpokladu, že zaměstnanci mohou vyslovit své mínění o chování společnosti nebo jejích zaměstnanců nebo o rozhodnutích, která považují za neetická. Vedení společnosti se zabývá všemi podněty a informacemi v souvislosti s porušováním tohoto etického kodexu a v případě potřeby také zajišťuje přijetí odpovídajících opatření

Firma ALPENTA s.r.o. je výrobcem chladících zařízení. Posláním společnosti je především naplnění požadavků zákazníků díky výrobě a dodávce spolehlivých a kvalitních chladících zařízení v konkurenční ceně. Minimálními dopady na životní prostředí jsou jedou z klíčových základních hodnot fungování společnosti.

Zásady environmentální a energetické politiky

– Usilovat o neustálé zlepšování systému environmentálního managementu a dále zavedením trvalých prověřování systému řízení v perspektivě ochrany životního prostředí a snižování energetické náročnosti procesů.

– V hodným způsobem systematicky vzdělávat a motivovat zaměstnance k aktivnímu přístupu a dodržování zásad ochrany životního prostředí.

– Plnit závazné povinnosti v oblasti ochrany životního prostředí, které se na naši společnost vztahují.

– Minimalizovat negativní dopady výrobních a podpůrných procesů na životní prostředí prostřednictvím preventivních opatření a systematicky předcházet znečišťování.

– Minimalizovat negativní dopad případných ekologicky havarijních situací.

– Podporovat nákup energeticky úsporných produktů a služeb a hledat možnosti ke snižování energetické náročnosti.

– Zavést a udržovat minimálně soulad s ekologickou a energetickou legislativou, nezvyšovat ekologickou zátěž okolí nad nutnou míru.

– Zavádět šetrnější technologie k životnímu prostředí.

– Zavádět spotřebu energie jako základní prvek v oblasti prevence znečišťování.

– Aktivně působit na dodavatele tak, aby jejich produkty nebo služby byly v souladu s kvalitativními a environmentálními kritérii společnosti.

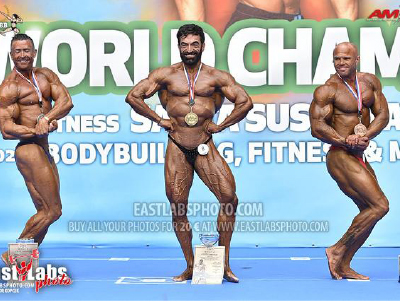

Sponzorujeme

Sportovec Bohumil Ševc – účastník Mistrovství Světa federace IFBB 2020 v klasické kulturistice masters od 40 do 49 let. Ve Španělské Santa Susanně se mu podařilo získat úžasné umístění, a to v podobě bronzové medaile.

Gratulujeme!

„Výsledek z MS ze Španělska je pro mě největším sportovním úspěchem, děkuji za podporu“

Bohumil Ševc